Introduction:

In today's world, technology has revolutionized every aspect of our lives. One of the most important technological innovations is the sensor pressure transmitter. It is a machine that measures and transmits the pressure of gases and liquids in various applications. This KEKUN article will focus on the sensor pressure transmitter and air flow meter explain its advantages, safety, use, service, quality, and applications.

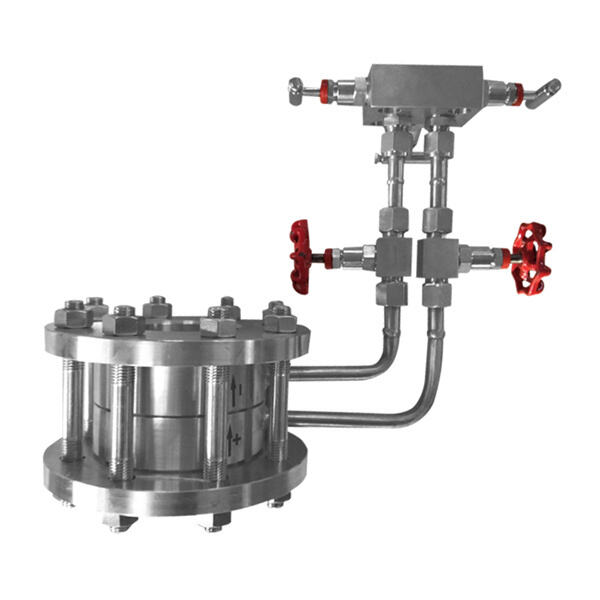

The sensor pressure transmitter has many advantages over traditional pressure measurement machines. Its accuracy is highly precise, with a range of measurement unparalleled capabilities. Furthermore, the KEKUN machine is highly durable and can withstand harsh conditions, making it ideal for use in hazardous environments. The oxygen flow meter sensor pressure transmitter is also very easy to use, with user-friendly software that allows for quick and easy calibration as well as maintenance.

One of the significant innovations of the sensor pressure transmitter is its ability to transmit data wirelessly and remotely. This KEKUN allows users to monitor and control processes from a distance, thus reducing the need for hands-on monitoring and increasing efficiency. Additionally, the differential pressure transducer machine's software allows for easy integration with other systems, making it a versatile and adaptable solution.

The sensor pressure transmitter is designed with safety in mind. It has various safety features that KEKUN ensure the machine will not fail, even under extreme conditions. Furthermore, the machine is also resistant to corrosion and other forms of damage that pressure differential transmitter could cause it to malfunction. This makes it an ideal machine for use in the oil and gas industry, where safety is of the utmost importance.

The sensor pressure transmitter has a wide range of uses in various industries, including manufacturing, pharmaceuticals, aerospace, and automotive. KEKUN is commonly used in processes that gas flow meter require precise measurements of liquids and gases, such as in chemical processing plants or oil refineries. Additionally, the machine is crucial in the operation of various types of machinery, including hydraulic systems and engines.

company certifications such ISO9001, CE SGS. addition, it several patents, like sensor pressure transmitter flow meters orifices, high-temperature water quality analysis equipment, that protected exclusive intellectual property rights.

sensor pressure transmitter 3000 square-meter production factory six product ranges, than 40 types products as well more a hundred models are used fields semiconductors water, environmental protection metals, petroleum, natural gas, medicine food.

sensor pressure transmitter items company included pressure transmitters liquid leveltransmitters. Gas analysers, thermocouples well as water quality analysts offered.

Universities,research institutes sensor pressure transmitter based technologies mainclientsour flowmeter. Theyprovides services more20,000 customersacross worldexports more60 countries

Using a sensor pressure transmitter is relatively uncomplicated. The KEKUN machine is typically connected via wires or wirelessly to a central control system, where its readings are monitored and analyzed. To obtain accurate readings, the flow transmitter machine must be calibrated regularly, and any issues that arise must be addressed promptly.

The sensor pressure transmitter requires regular maintenance to ensure it continues to function correctly. KEKUN is important to perform regular inspections of the machine to check for any signs of wear or damage. Additionally, calibration should be performed regularly to ensure that the gas flow gauge machine is providing accurate readings. If any issues arise, they should be addressed by a qualified technician promptly.

Quality is of the utmost importance when it comes to the sensor pressure transmitter. The KEKUN machine must be manufactured to strict standards in order to ensure its accuracy and reliability. It is crucial to choose a high-quality built machine to last and can withstand the demands of various applications.

Copyright © Weibao Information Technology (Shanghai) Co,Ltd. All Rights Reserved